By John Kemp, senior market analyst at Reuters

Global manufacturing growth has started to decelerate as supply chain problems, the rising cost of energy and raw materials, and the conflict between Russia and Ukraine take their toll.

Slower growth in manufacturing output and freight transport is inevitable after the recovery from the pandemic, when consumer spending shifted to merchandise from services. As quarantines and other social-distancing restrictions are lifted, spending is being redirected back towards services such as transport, tourism and hospitality, sapping some of the demand for goods.

Slower manufacturing and freight growth will be quietly welcomed by policymakers since it is likely to ease supply chain bottlenecks and take some of the heat out of energy prices and inflation.

But as the sector loses momentum, it will become more vulnerable to shocks or policy errors that could turn a mid-cycle slowdown into a cycle-ending recession.

The range of possible outcomes for growth and inflation is wide and the room for policy errors is very narrow.

FADING MOMENTUM

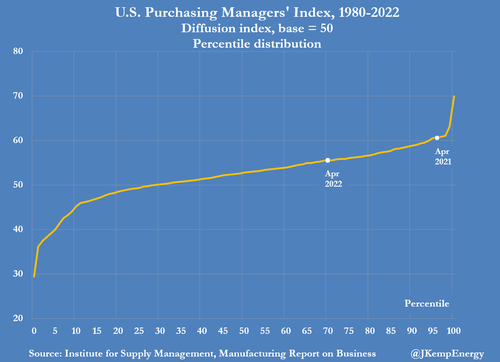

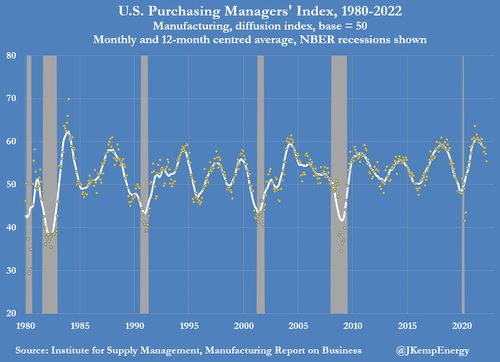

U.S. manufacturers reported another fairly widespread expansion in business activity last month but fewer firms are reporting growth compared with 2021. The Institute for Supply Management’s purchasing managers’ index slipped to 55.4 in April from 57.1 in March and 60.6 at the same point last year.

The composite indicator is in the 69th percentile for all months since 1980 down from the 96th percentile a year ago.

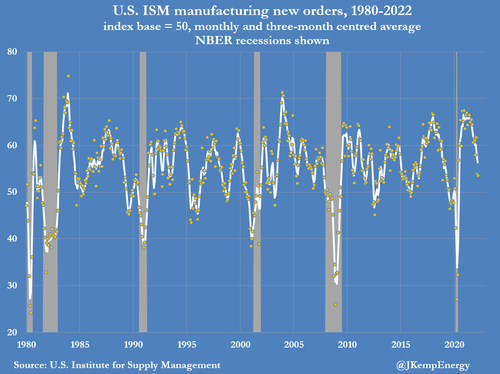

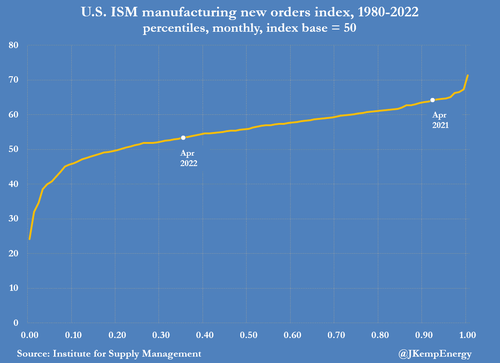

The new orders measure, which is the most forward-looking component of the index, has slipped to the 35th percentile from the 93rd a year ago.

The relative weakness of new business likely portends a further slowdown in manufacturing growth over the next six months.

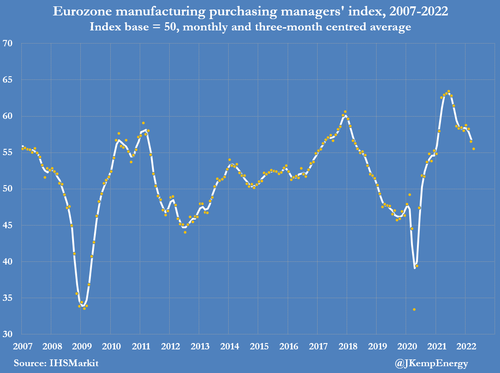

In the eurozone, manufacturers also reported a slower expansion last month, with the purchasing managers’ index down to 55.5 in April from 56.5 in March and 62.9 last year.

The region’s purchasing index has dipped to the 74th percentile for all months since 2006 compared with the 99th percentile a year ago.

European manufacturers are likely to experience an even deeper slowdown in the months ahead as sanctions on Russian coal, oil and possibly gas raise input costs and squeeze consumer and business spending.

In North America and Europe, the manufacturing sector is still expanding, but momentum is ebbing fast and the slowdown is likely to deepen as inflation and higher interest rates squeeze household spending.

CHINA IN TROUBLE

In China, manufacturers have already been hit far harder than in the other regions because they are also struggling with increasingly frequent coronavirus outbreaks and lockdowns.

China’s manufacturing index slipped to 47.4 in April from 49.5 in March and 51.1 in April 2021, according to the country’s National Bureau of Statistics.

The index has fallen to its lowest since February 2020, when the first wave of the pandemic was raging, and before that January 2009, when the economy was in the midst of the recession caused by the financial crisis.

China’s manufacturers already appear to be on the brink of recession as lockdowns close factories and disrupt supply chains.

Over the last week, the top message from policymakers and the state-run media has been the need to restart the economy while maintaining epidemic controls, an acknowledgement of how serious the slowdown has become.

By John Kemp, senior market analyst at Reuters

Global manufacturing growth has started to decelerate as supply chain problems, the rising cost of energy and raw materials, and the conflict between Russia and Ukraine take their toll.

Slower growth in manufacturing output and freight transport is inevitable after the recovery from the pandemic, when consumer spending shifted to merchandise from services. As quarantines and other social-distancing restrictions are lifted, spending is being redirected back towards services such as transport, tourism and hospitality, sapping some of the demand for goods.

Slower manufacturing and freight growth will be quietly welcomed by policymakers since it is likely to ease supply chain bottlenecks and take some of the heat out of energy prices and inflation.

But as the sector loses momentum, it will become more vulnerable to shocks or policy errors that could turn a mid-cycle slowdown into a cycle-ending recession.

The range of possible outcomes for growth and inflation is wide and the room for policy errors is very narrow.

FADING MOMENTUM

U.S. manufacturers reported another fairly widespread expansion in business activity last month but fewer firms are reporting growth compared with 2021. The Institute for Supply Management’s purchasing managers’ index slipped to 55.4 in April from 57.1 in March and 60.6 at the same point last year.

The composite indicator is in the 69th percentile for all months since 1980 down from the 96th percentile a year ago.

The new orders measure, which is the most forward-looking component of the index, has slipped to the 35th percentile from the 93rd a year ago.

The relative weakness of new business likely portends a further slowdown in manufacturing growth over the next six months.

In the eurozone, manufacturers also reported a slower expansion last month, with the purchasing managers’ index down to 55.5 in April from 56.5 in March and 62.9 last year.

The region’s purchasing index has dipped to the 74th percentile for all months since 2006 compared with the 99th percentile a year ago.

European manufacturers are likely to experience an even deeper slowdown in the months ahead as sanctions on Russian coal, oil and possibly gas raise input costs and squeeze consumer and business spending.

In North America and Europe, the manufacturing sector is still expanding, but momentum is ebbing fast and the slowdown is likely to deepen as inflation and higher interest rates squeeze household spending.

CHINA IN TROUBLE

In China, manufacturers have already been hit far harder than in the other regions because they are also struggling with increasingly frequent coronavirus outbreaks and lockdowns.

China’s manufacturing index slipped to 47.4 in April from 49.5 in March and 51.1 in April 2021, according to the country’s National Bureau of Statistics.

The index has fallen to its lowest since February 2020, when the first wave of the pandemic was raging, and before that January 2009, when the economy was in the midst of the recession caused by the financial crisis.

China’s manufacturers already appear to be on the brink of recession as lockdowns close factories and disrupt supply chains.

Over the last week, the top message from policymakers and the state-run media has been the need to restart the economy while maintaining epidemic controls, an acknowledgement of how serious the slowdown has become.